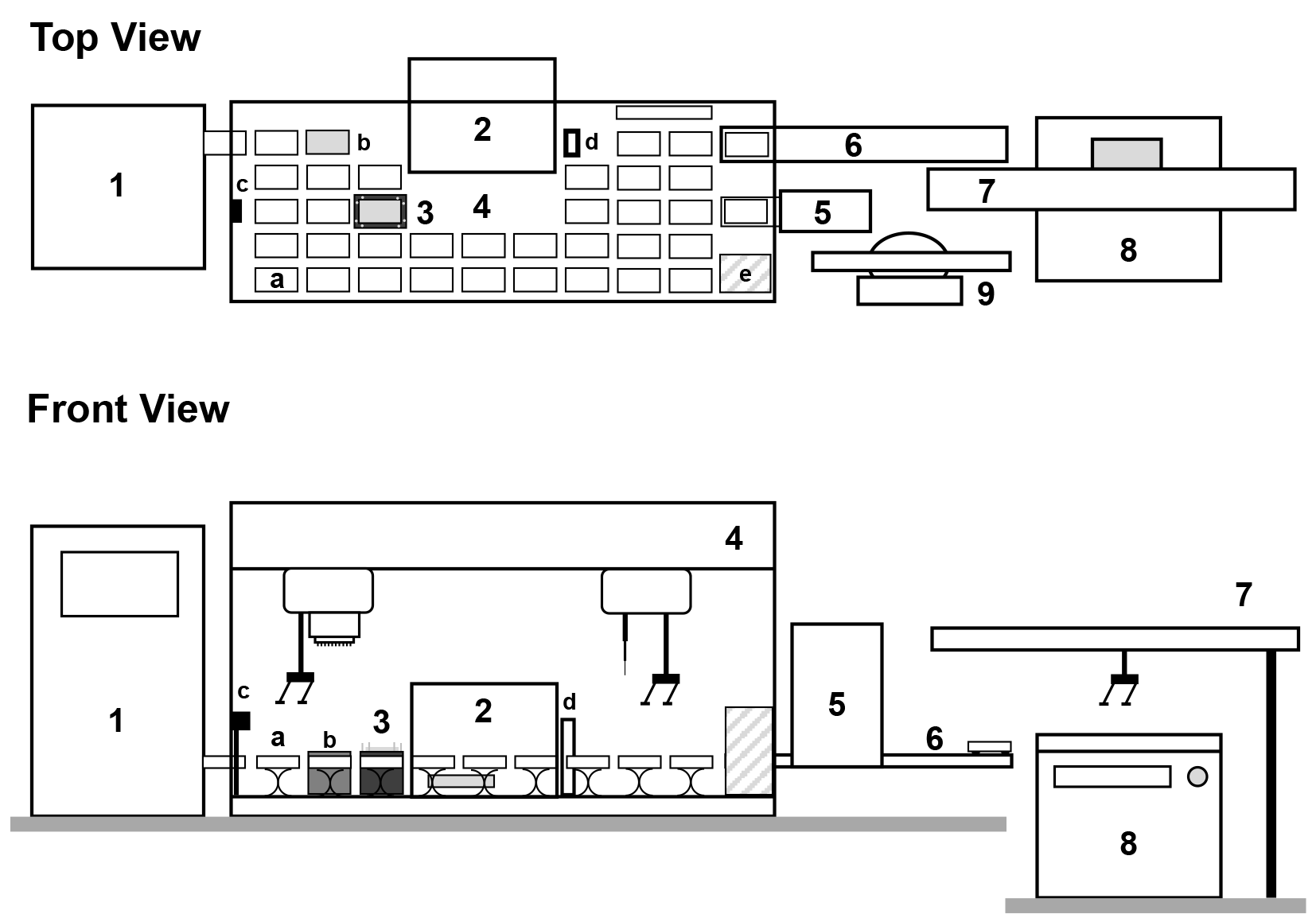

Features

- ALP positions to place labware (up to 4 MTP or 2 DWP per position)

- Tip washing station for the 96-multichannel pipette

- Barcode reader

- Span8 washing station

- Trash for the disposal of used labware or empty tip boxes.

- Pod 1: left gripper and 96-multichannel pipette (5-1200 μL)

- Pod 2: right gripper and Span8 multichannel pipette (5-1200 μL). Pipettes from Span8 can adjust the wide distance between each other (Y axis) and each of the pipettes can move independently in height (Z axis)

What is this for?

The Biomek i7 is the core of our robotic platform, where all the liquid handling and most of the labware movement is performed. Thus, on the Biomek i7 deck takes place the colony picking and the culture and reaction preparation. Depending on to and from which position (ALP) the labware must be moved the grippers on Pods 1 and 2 will be used. Similarly, depending on the characteristics of the liquid handling to be performed the 96-MC pipette or the Span8 will be selected. For instance, colony picking or pipetting from eppis/vials is done with the Span8 thanks to its flexibility, while most of the reaction liquid transfers are performed by the 96-MC because is faster.

The 96-well tip washing station is connected to a water or isopropanol 70% reservoir through a peristaltic pump so tips attached to the 96-multichannel pipette can be washed, and therefore reused. On the other hand, the Span8 washing station is used for purging the Span8 syringes.

Barcodes present in the labware can be read by the Fly-By barcode reader, allowing us to track all the labware used throughout the method.

Additionally, we added a trash to dispose of the labware that is no longer necessary on deck.

Click to watch the full video.

Click to watch the full video.

.

.